Obstacles in Overweight Truck Screening

Currently, overweight truck enforcement is generally conducted at static weighing stations or by traffic troopers using a portable weighing scale. Static weighing stations are equipped with truck scales (trucks stop for weighing) or a weigh-in-motion (WIM) system (trucks continue moving while being weighed) to measure the axle weight as well as gross vehicle weight (GVW). As this system requires truck drivers to pull into the weighing station, it is practically impossible to filter all overweight trucks. Similarly, enforcement by traffic troopers is only applied when the truck configuration (size and weight) is suspicious, making it infeasible to detect all overweight trucks. These types of enforcement processes require large amounts of time and resources and are not very effective, resulting in low efficiency.

Based on a former project with New Jersey Department of Transportation (NJDOT), the annual truck count in New Jersey was 45 million in 2011 and approximately 6.4% of trucks were overweight trucks. The truck count was collected from all WIM sites in New Jersey, and trucks that violated the Federal Bridge Formula B were sorted as overweight trucks. In 2009, the NJDOT published the annual vehicle size and weight limit enforcement certification.This report summarizes the number of vehicles weighed and/or screened by four weighing stations in NJ (see Figure 1) as 1,006,749 in 2009. Only 0.142% (1,430 trucks) of screened trucks were ticketed due to an overweight condition, meaning only 2.2% of the actual overweight trucks were ticketed through the current system.

Additionally, the number and weight of trucks has been increasing over the last decade, but the level of enforcement has decreased, indicating that truck companies and drivers know how to bypass weigh stations or avoid traffic troopers. Therefore, there is a need to find more efficient methods for overweight truck enforcement to improve the safety of transportation networks. Advanced Weigh-in-Motion (A-WIM) technologies present a reasonable and practical alternative.

Implementing A-WIM Systems

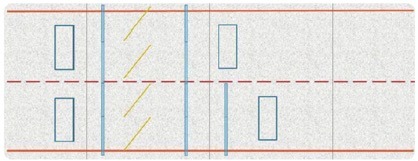

It is important that any implemented A-WIM system have a proven, high degree of accuracy to prevent challenges to its use. Highly accurate WIM systems have been developed by TDC Systems in the U.K, Camea in the Czech Republic and NewConsTech in Korea. The Korean Expressway Corporation (an agency similar to the New Jersey Turnpike Authority or New York State Thruway Authority) collaborated with NewConsTech on weight violation enforcement.The system utilizes the Quartz sensor as the weighing medium, induction loops to separate the vehicles, and temperature sensors and wandering sensors to increase the accuracy. This system can measure the GVW within ±2.5% error. KEC implemented this WIM system for weight violation enforcement on highways in Korea, and the overweight truck ratio was reduced from 9.7% to 2.4% over 16 weeks. As the enforcement system currently in use in the U.S. has been shown to be inefficient, there is an opportunity to investigate implementing an advanced WIM system to improve future enforcement.

Additionally, the number and weight of trucks has been increasing over the last decade, but the level of enforcement has decreased, indicating that truck companies and drivers know how to bypass weigh stations or avoid traffic troopers. Therefore, there is a need to find more efficient methods for overweight truck enforcement to improve the safety of transportation networks. Advanced Weigh-in-Motion (A-WIM) technologies present a reasonable and practical alternative.

Research Objectives

The research team will first establish a test bed for the development of the advanced WIM (A-WIM) system by collaborating with local transportation agencies for the selection of the test bed site near a static weighing station. Then, it will develop a set of calibration procedures to guarantee that the level of accuracy is reached and preserved over time. These procedures will include, but are not limited to, the effect of temperature, humidity, and pavement type.

Both quartz and piezoelectric sensors will be instrumented at the test bed. The sensors will be evaluated using a calibration truck as well as typical truck configurations. The methodology will be used to develop the A-WIM system for future autonomous weight screening and/or enforcement.

The team will also investigate the possibility of integrating weighing sensors with additional devices such as thermal visual recorders. The cameras will collect plate identification numbers and will be intelligently controlled such that records are stored only when certain conditions are met (e.g. when maximum gross weight is exceeded). The visual information will provide additional support for truck weight screening and/or future autonomous enforcement operations.

Related Media

WIM sensor layout for A-WIM (Quartz sensor, wandering sensor, and inductive loop)